Coflexip® Rim Fire Protection System

99,9% of all fires on floating roof tanks start as a Rim Fire. A rim fire situation is still the most easy to extinguish, especially when you have the Coflexip® Rim Fire Foam System installed.

The Coflexip® Rim Fire Foam System is a fully engineered, 100% maintenance free system with an excellent reliability. Within 3 minutes after the flow of foam has started the rim will be filled completely with foam, stopping the fire completely. Numerous full-size tests have been carried out to confirm this timescale, it is part of the standard design package.

In this short time the structural damage caused by the fire will be close to none. Not to mention the environmental damage prevented compared to a larger fire.

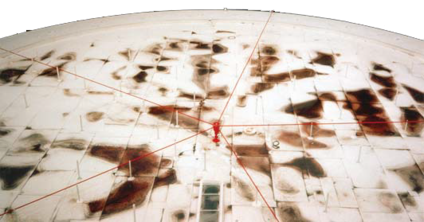

This system is a closed system, there is no influence on its effectivity by strong winds, low roof position, strong rainfall or other external phenomena. Inside the tank there is a Coflexip® flexible steel pipe, connected to a rigid pipe which is placed through the roof. On the roof, on top of this feed through pipe a stainless steel manifold is mounted, where the foam will be divided into 2” fixed piping, which leads the foam at the seal of the rim. The number of 2”radial piping is determined by the 3 minute requirement, and the diameter of the tank.

Coflexip® will supply detailed engineering drawings how the flexible pipe has to be installed in the storage tank. TReK STS will help and guide during installation, perform in-between and final inspections, to ensure a trouble free operation.

Compared to conventional over the top systems our system is a small investment, reducing costs on materials and labour. Secondly once installed, it will save hugely on your maintenance costs.

The Coflexip® foam system is also adaptable to tanks with a fixed roof, with an internal floater or even as a floating unit itself. Uniquely simple, the installation is protected by the product itself if any explosive event occurs, unlike systems, based on the roof, which will be exposed to the blast itself.

It will never interfere with equipment inside the tank, even with the roof in the lowest position. The unique repeatable lay pattern configuration takes limited space inside the tank. Even though the flexible pipe moves freely, due to its construction it will lay itself on the tankbottom in the same position and pattern when the roof is lowered.